Ajusto-Spede Motor Repair Services in Michigan

A&C Electric provides Ajusto-Spede motor repair to companies in Michigan, Indiana and Ohio. We work with DSI Dynamatic, Eaton and Louis Allis drives, offering quick diagnostics and in-house service capabilities for every model. Contact us today for a quote on Ajusto-Spede motors across the Midwest.

How Ajusto-Spede Drives Work

Ajjusto-Spede Drives use an air-cooled, adjustable speed clutch paired with a NEMA B AC induction motor to deliver constant torque across a variable speed range. There’s no physical contact between input and output, which helps reduce wear and extend motor life.

Each drive includes:

- TEFC construction and C-Face endbells

- Internal tachometer generator for real-time feedback

- DC excitation to the clutch coil via the controller

Speed is regulated by comparing the tachometer signal to a reference point within the controller. This feedback loop produces smooth response with reduced shock loading—ideal for high-inertia loads and precision industrial motor control.

Ajusto-Spede systems deliver a 34:1 speed range at 250% rated torque, making them ideal for high-load startups. Because Ajusto-Spede drives differ significantly from standard motor types, they require specialized knowledge and equipment. A&C Electric technicians have decades of experience repairing industrial electric motors and strive to save customers money by reducing lead time and spare motor costs.

Variable Speed Drive Models We Service

-

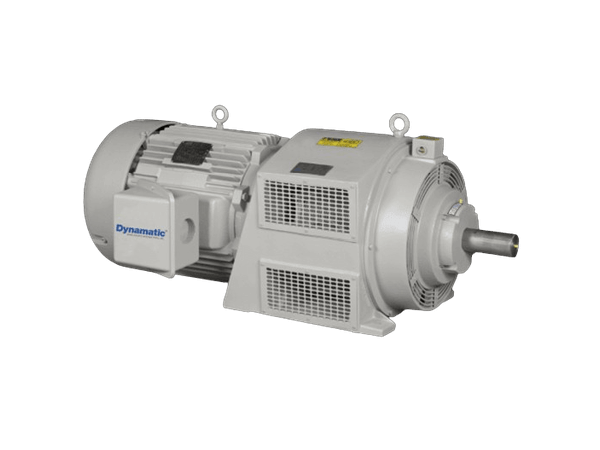

AS & FAS Drives: Smooth, Compact Speed Control

AS & FAS Drives: Smooth, Compact Speed ControlDynamatic AS and FAS drives offer tight speed control with simple drop-in installation, especially in fractional horsepower ranges.

- Available in 1/4 to 1.5 HP units

- Compatible with single or three-phase power

- 34:1 speed range and 250% rated motor torque

- Built with permanently lubricated bearings and C-face mounts

- Matches overload requirements and existing wiring

- No special training or wiring changes required

-

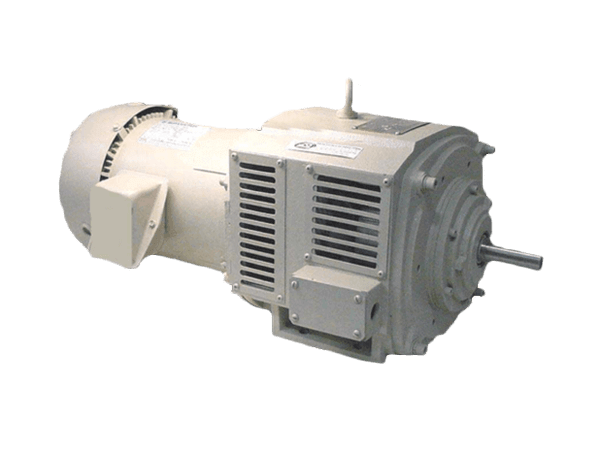

AT Drives: Built for Stamping Presses

AT Drives: Built for Stamping PressesOriginally engineered for press applications, AT drives provide rugged performance and consistent torque under changing loads.

- 1–200 HP capacity with tachometer feedback

- Speed control within 0.5% from no load to full load

- 250% rated torque for high-inertia startups

- Minimal harmonics with low-maintenance design

- Small controller footprint with PLC compatibility

- Used in presses, kilns, bitumen pumps and cold feed bins

-

DCD Drives: Low-Maintenance in Harsh Conditions

DCD Drives: Low-Maintenance in Harsh ConditionsDCD drives combine durability with simplicity for demanding environments like mining and asphalt processing.

- Air-cooled, adjustable speed clutch with AC induction motor

- Self-cleaning rotor for dust and debris resistance

- 250% startup torque and consistent speed regulation

- TEFC design with no routine maintenance

- Drop-in NEMA and IEC motor frame compatibility

- Reliable performance in conveyor and aggregate systems

Our team repairs and refurbishes Ajusto-Spede and Dynamtic industrial motors using precision tools, proper handling techniques and decades of hands-on experience. Each motor is returned quickly and at a significantly lower cost than replacement.

AS Motor Repairs

- AS-140104-0145

- AS-140104-0190

- AS-140106-0145

- AS-140106-0190

- AS-140154-0145

- AS-140154-0190

- AS-140204-0145

- AS-140204-0190

- AS-140304-0145

- AS-140304-0190

- AS-180156-0145

- AS-180156-0190

- AS-180206-0145

- AS-180206-0190

- AS-180304-0145

- AS-180304-0190

- AS-180306-0145

- AS-180306-0190

- AS-180504-0145

- AS-180504-0190

- AS-210506-0145

- AS-210506-0190

- AS-210754-0145

- AS-210754-0190

- AS-211004-0145

- AS-211004-0190

- AS-250756-0145

- AS-250756-0190

- AS-251006-0145

- AS-251006-0190

- AS-251504-0145

- AS-251504-0190

- AS-252004-0145

- AS-252004-0190

- AS-271506-0145

- AS-271506-0190

- AS-272004-0145

- AS-272004-0190

- AS-272006-0145

- AS-272006-0190

- AS-272504-0145

- AS-272504-0190

- AS-272506-0145

- AS-272506-0190

- AS-273004-0145

- AS-273004-0190

- AS-274004-0145

- AS-274004-0190

- FD-2541-4001

- FD-2541-4002

- FD-2543-4001

- FD-2543-4002

- FD-5021-4001

- FD-5021-4002

- FD-5023-4001

- FD-5023-4002

- FD-5041-4001

- FD-5041-4002

- FD-5043-4001

- FD-5043-4002

- FD-7521-4001

- FD-7521-4002

- FD-7523-4001

- FD-7523-4002

- FD-7541-4001

- FD-7541-4002

- FD-7543-4001

- FD-7543-4002

- FD-9523-4001

- FD-9523-4002

- FD-9923-4001

- FD-9923-4002

- FD-9941-4001

- FD-9943-4001

- FD-9943-4002

AT Motor Repairs

- AT-140014-0145

- AT-140014-0190

- AT-140024-0145

- AT-140024-0190

- AT-180034-0145

- AT-180034-0190

- AT-180054-0145

- AT-180054-0190

- AT-180074-0145

- AT-180074-0190

- AT-210074-0145

- AT-210074-0190

- AT-210104-0145

- AT-210104-0190

- AT-210154-0145

- AT-210154-0190

- AT-250154-0145

- AT-250154-0190

- AT-250204-0145

- AT-250204-0190

- AT-250254-0145

- AT-250254-0190

- AT-280254-0145

- AT-280254-0190

- AT-280304-0145

- AT-280304-0190

- AT-280404-0145

- AT-280404-0190

- AT-280504-0145

- AT-280504-0190

- AT-320256-0145

- AT-320256-0190

- AT-320304-0145

- AT-320304-0190

- AT-320306-0145

- AT-320306-0190

- AT-320404-0145

- AT-320404-0190

- AT-320406-0145

- AT-320406-0190

- AT-320504-0145

- AT-320504-0190

- AT-320604-0145

- AT-320604-0190

- AT-320754-0145

- AT-320754-0190

- AT-360506-0145

- AT-360506-0190

- AT-360604-0145

- AT-360604-0190

- AT-360606-0145

- AT-360606-0190

- AT-360754-0145

- AT-360754-0190

- AT-361004-0145

- AT-361004-0190

- AT-361254-0145

- AT-361254-0190

- AT-440756-0145

- AT-440756-0190

- AT-441004-0145

- AT-441004-0190

- AT-441006-0145

- AT-441006-0190

- AT-441254-0190

- AT-441256-0145

- AT-441256-0190

- AT-441504-0145

- AT-441504-0190

- AT-442004-0145

- AT-442004-0190

DCD Motor Repairs

- DCD-132030-4141

- DCD-132050-4121

- DCD-132050-4141

- DCD-132075-4121

- DCD-132100-4121

- DCD-160075-4141

- DCD-160100-4141

- DCD-160150-4121

- DCD-160150-4141

- DCD-160200-4121

- DCD-160250-4121

- DCD-180150-4141

- DCD-180200-4141

- DCD-180250-4121

- DCD-180250-4141

- DCD-180300-4121

- DCD-180300-4141

- DCD-225300-4141

- DCD-225400-4141

- DCD-225500-4141

- DCD-225600-4141

- DCD-225750-4141

Contact A&C Electric for expert Ajusto-Spede repair in Michigan and surrounding states.