A&C Electric – Expert DC Motor Repair in Michigan, Ohio, Illinois & Indiana

At A&C Electric, we specialize in industrial and commercial DC motor repair for businesses across Michigan, Ohio, Illinois, and Indiana. Our mission is simple: keep your motors running at peak performance while minimizing costly downtime.

DC motors are the backbone of many manufacturing, processing, and municipal operations. From precision control in conveyor systems to powering heavy-duty machinery, they play a critical role in production efficiency. When a DC motor fails, it can halt entire operations. That’s why our team delivers fast, reliable, and cost-effective DC motor repair services—getting you back to work quickly.

We are an EASA-certified repair shop with decades of experience restoring DC motors to OEM or better specifications. Whether you need rewinding, brush replacement, armature repair, or complete refurbishment, A&C Electric is your trusted Midwest partner.

Why Choose A&C Electric for DC Motor Repair?

Businesses throughout Michigan, Ohio, Illinois, and Indiana choose A&C Electric because we combine technical expertise, advanced diagnostic equipment, and a customer-first approach.

Our Advantages:

- Experienced Technicians – Skilled in repairing DC motors from all major manufacturers.

- Advanced Testing – We use precision instruments to detect electrical and mechanical faults quickly.

- Quality Assurance – Every repair is tested under load to ensure long-term reliability.

- Fast Turnaround – Downtime costs money, so we prioritize quick yet thorough repairs.

- Emergency Service – 24/7 breakdown support available throughout our service areas.

Our DC Motor Repair Services

We provide full-service DC motor repairs for all types and sizes, from fractional horsepower units to large industrial motors.

-

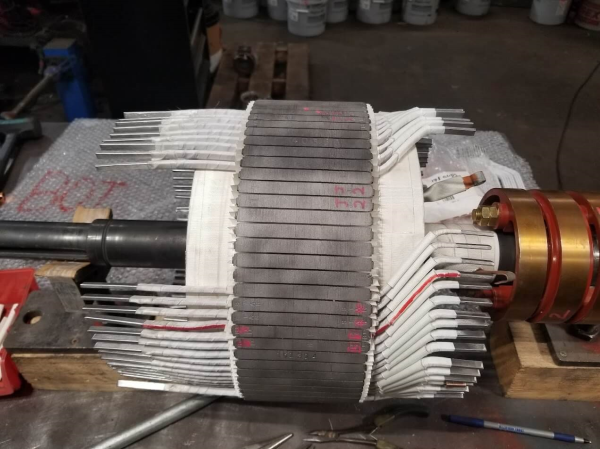

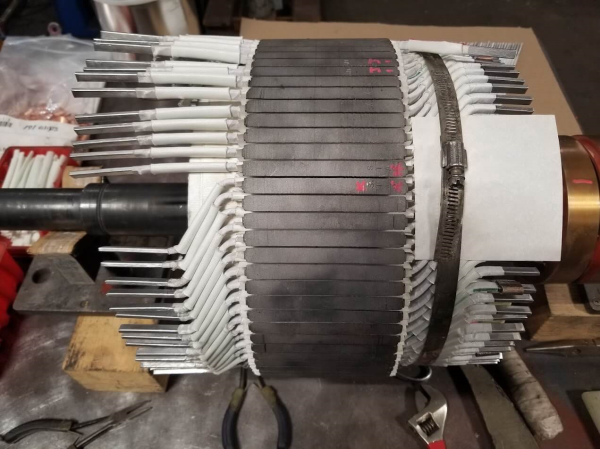

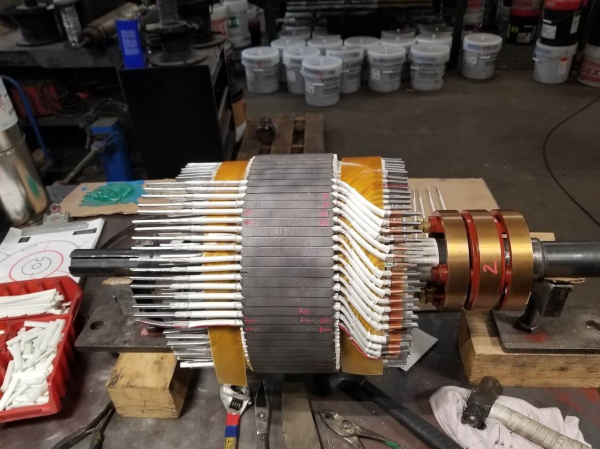

DC Motor Rewinding

Our rewinding process restores damaged coils using high-grade copper wire and insulation materials rated for demanding industrial environments.

-

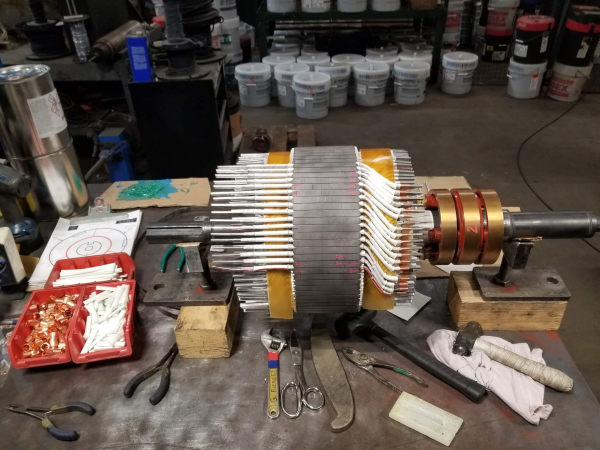

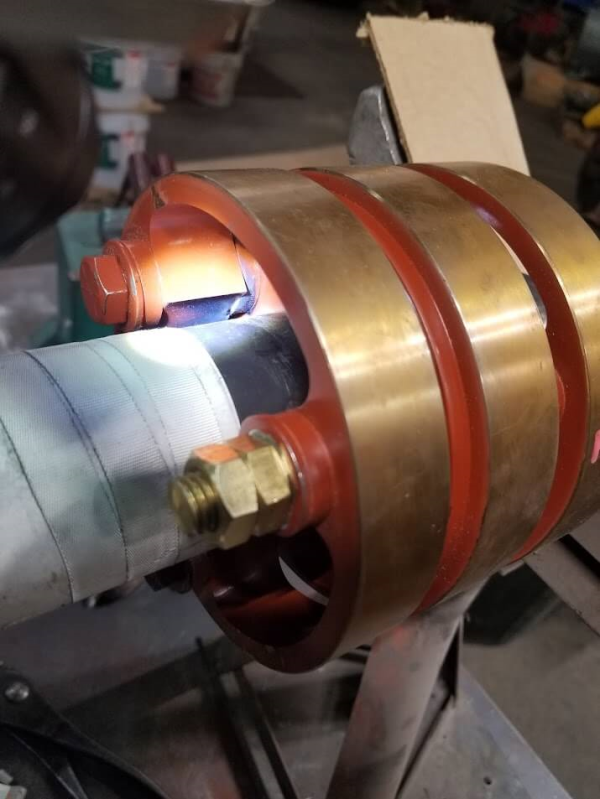

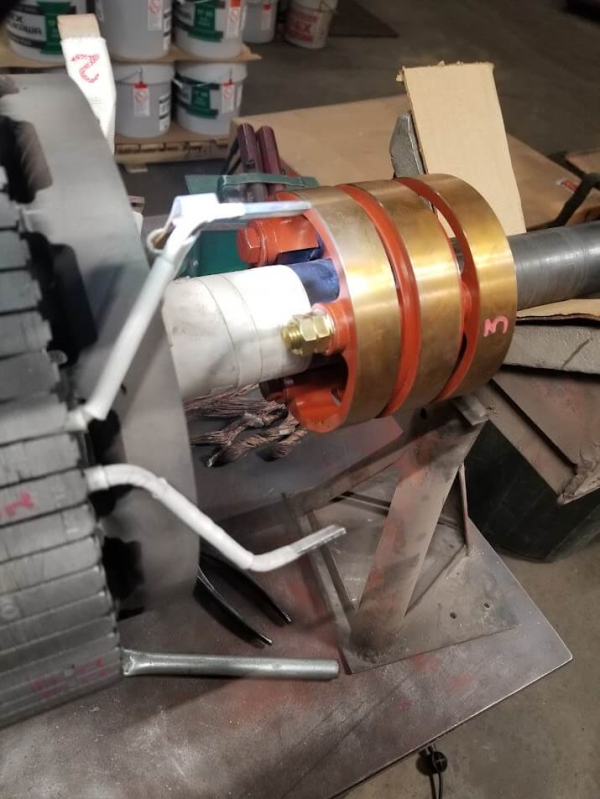

Commutator & Armature Repair

We resurface, undercut, and repair commutators, as well as balance and rewind armatures, ensuring smooth electrical contact and extended motor life.

-

Brush Replacement & Brush Holder Repair

Worn or damaged brushes reduce efficiency and cause overheating. We replace brushes and repair holders to restore optimal performance.

-

Bearing Replacement & Shaft Repair

We replace bearings, repair shafts, and restore precise alignment to reduce wear and vibration.

-

Dynamic Balancing

Proper balance reduces vibration, increases efficiency, and prevents premature bearing and winding wear.

-

Electrical Testing & Diagnostics

We perform megger testing, surge comparison, load testing, and high-pot testing to detect faults and confirm repairs meet strict performance standards.

-

Preventive Maintenance

Our scheduled maintenance programs catch small issues before they become costly breakdowns.

Industries We Serve

Our DC motor repair services support a wide range of industries across the Midwest:

- Automotive Manufacturing

Assembly lines, conveyors, robotics. - Steel & Metal Processing

Heavy-duty rolling mill motors. - Food & Beverage Processing

Motors for mixers, conveyors, and packaging. - Water & Wastewater Treatment

Pump motors and control systems. - Agriculture & Farming

Motors for grain handling, irrigation, and feed systems. - Plastics & Chemical Processing

DC drives in demanding environments.

Serving the Midwest with Local Expertise

We provide fast, dependable DC motor repair in:

- Michigan

Detroit, Grand Rapids, Lansing, Flint, and beyond. - Ohio

Cleveland, Columbus, Toledo, Cincinnati. - Illinois

Chicago, Rockford, Peoria, Springfield. - Indiana

Indianapolis, Fort Wayne, Evansville.

Our DC Motor Repair Process

-

Inspection & Evaluation

We thoroughly inspect mechanical and electrical components to determine repair needs.

-

Disassembly & Cleaning

Removing all dirt, oil, and contaminants for a fresh start.

-

Precision Repairs

Rewinding, machining, and part replacement as needed.

-

Reassembly & Testing

All motors are reassembled with new seals and gaskets, then tested under load.

-

Final Quality Check

Verifying that your motor meets or exceeds OEM performance.

Emergency DC Motor Repair – 24/7 Availability

When production stops, every second counts. That’s why A&C Electric offers emergency DC motor repair services around the clock. We can pick up, repair, and return your motor as quickly as possible, reducing costly downtime.

DC Motor Repair Process

Our team follows a proven repair workflow using advanced equipment and precision testing:

-

Data Motor nameplate data is recorded.

-

Inspection A visual inspection of any damage to the motor.

We check for

- Damaged Leads/Terminals

- Worn output shaft/keyways

- Cracks in end bells or covers

- Cracks in bases/feet

-

Job Ticket We complete to full write up off all motor data.

Including

- All winding tests (Resistance, Meg Ω, Continuity) on the armature and field windings

- All bearing sizes

- All seal sizes

- Feedback Tests (Tachometer/Encoder)

-

Motor Disassembly

- Bearing and seal sizes are recorded

- More winding tests are performed (Surge and HiPOT tests) on the armature and field windings

- Bar-to-Bar test is performed on the commutator

- Bearing fits are measured on shaft and End bell

- All brushes and holder sizes are recorded

- Brake torque is measured as well as resistance and Meg Ω

- Armature is then washed and baked in oven

- Field windings are washed and baked in oven

-

Assembly

- New bearings are installed

- New seals are installed

- If required, new armature windings are installed

- If required, new field windings are installed

- New brushes and brush holders are installed

- Commutator is undercut or replaced if necessary

- Brakes are rebuilt or replaced depending on manufacturer design.

-

Rotor Balancing and Testing

- Rotor is run through a full vibration diagnostic

-

Run Testing

- Every Motor is Run for a minimum of 1 hour using one of our drives.

- We use Siemens S110, S120, IndraDrive, AB Kinetix 300, Yaskawa 7, and AMC drives

-

Service Report

- A Final 3-page Service Report is filled out

- Pinout diagram for power and feedback is provided

- Brake torque is recorded a final time for our Service Reports

- A photo of nameplate and motor is attached

- A motor tag is installed on motor with QR code linking Service Report and Job Histories

- If requested, a YouTube link is attached to the service report of motor

Every completed repair includes a detailed service report outlining what was done and why. This helps reduce future downtime through proactive maintenance.

Contact A&C Electric for dependable DC motor repair in Michigan, Ohio and Indiana.

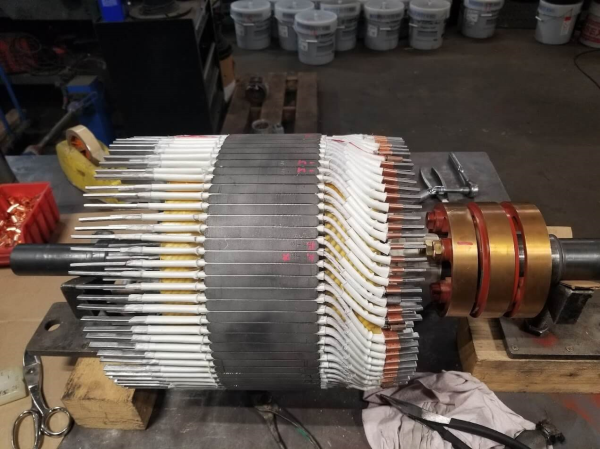

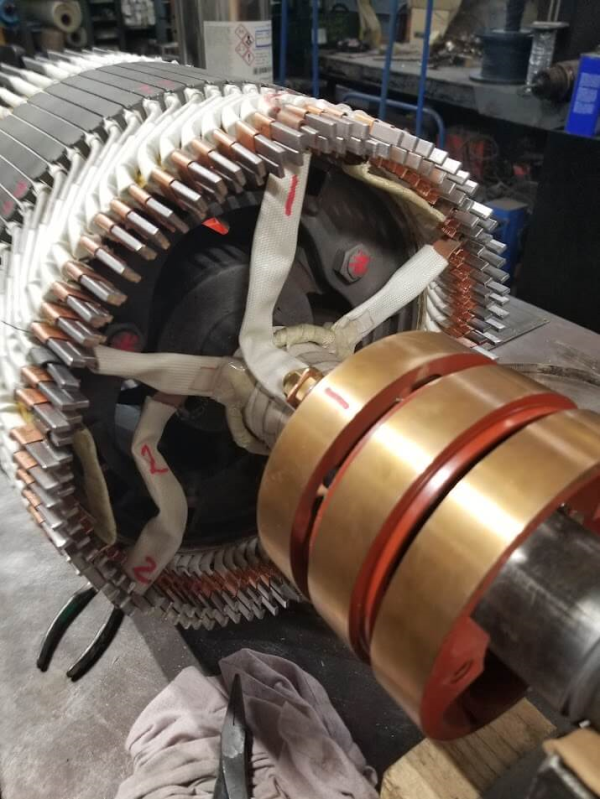

DC Motor Repairs in Action

Manufacturers We Service

We repair DC motors from leading manufacturers across a wide range of applications: