A&C Electric – Expert AC Motor Repair in Michigan, Ohio, Illinois & Indiana

At A&C Electric, we specialize in industrial and commercial AC motor repair across Michigan, Ohio, Illinois, and Indiana. We know that every minute of downtime costs money, which is why our technicians deliver fast, high-quality AC motor service that gets you back to full operation—on time and on budget.

We repair, rewind, and rebuild AC motors of all sizes and brands. Whether you need a small fractional horsepower motor fixed or a large industrial motor restored, we’ve got the tools, expertise, and capacity to handle it. Our goal is simple: keep your motors running at peak efficiency while extending their service life.

Why A&C Electric is the Midwest’s Trusted AC Motor Repair Company

Businesses across the Midwest rely on A&C Electric because we deliver precision repairs, competitive pricing, and unmatched customer service.

Benefits of choosing us:

- Highly Experienced Technicians – Skilled in repairing all makes and models of AC motors.

- Advanced Diagnostic Tools – Identify problems quickly and accurately.

- EASA-Certified Repairs – Ensuring motors meet or exceed OEM standards.

- 24/7 Emergency Service – We’re available when you need us most.

- Regional Coverage – Serving Michigan, Ohio, Illinois, and Indiana with local expertise.

Our Comprehensive 3-Phase AC Motor Repair Services

-

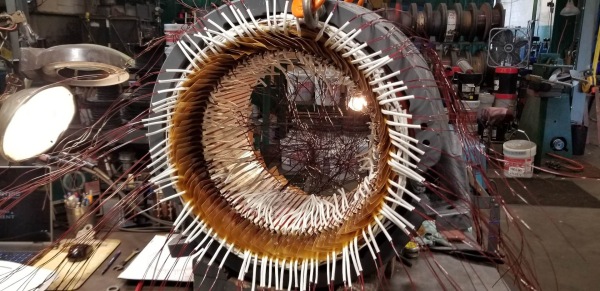

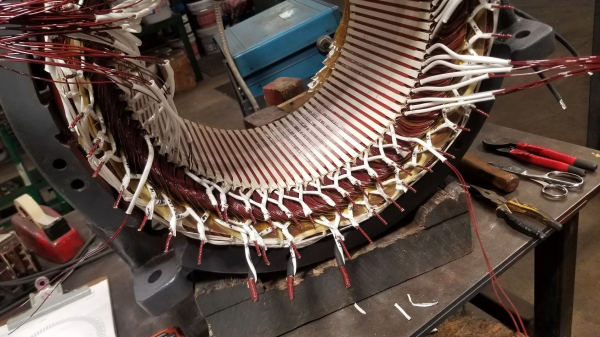

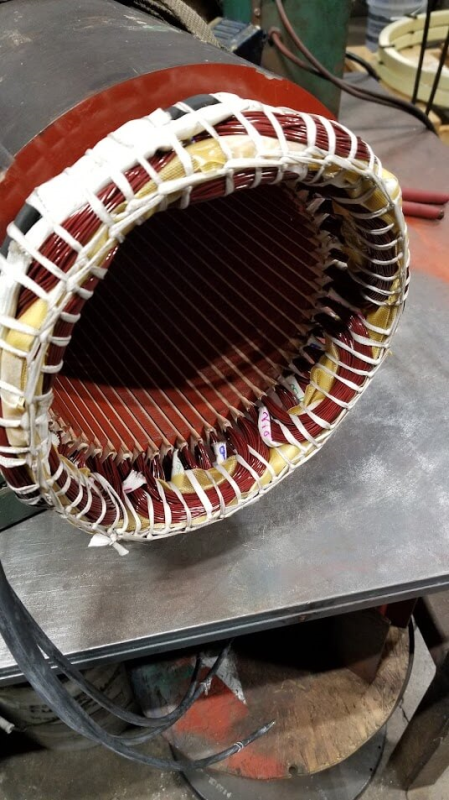

AC Motor Rewinding

We perform high-quality rewinding services using premium wire and insulation materials, restoring motors to factory performance or better.

-

Bearing Replacement & Shaft Restoration

We replace worn bearings, repair shafts, and ensure precise alignment for smoother operation and longer life.

-

Dynamic Balancing

We eliminate vibration with precision balancing, increasing efficiency and reducing mechanical stress.

-

Electrical Testing & Diagnostics

We use advanced testing methods—surge, insulation resistance, and high-pot testing—to catch issues before they cause failure.

-

Preventive Maintenance Programs

We offer scheduled maintenance services to prevent costly breakdowns and extend the life of your AC motors.

Industries We Serve

Our clients span multiple sectors throughout the Midwest:

- Automotive

AC motor repair for assembly lines, robotics, and conveyors. - Steel & Metal

Durable repairs for high-load and high-heat applications. - Food Processing

Sanitary, reliable motor service for production facilities. - Water Treatment

Repair and maintenance for critical pump motors. - Agriculture

Keeping irrigation and grain handling systems running.

Local Service with Regional Reach

We proudly provide AC motor repair in:

- Michigan

Detroit, Grand Rapids, Lansing, Flint, and more. - Ohio

Cleveland, Columbus, Toledo, Cincinnati, and surrounding areas. - Illinois

Chicago, Rockford, Peoria, Springfield, and beyond. - Indiana

Indianapolis, Fort Wayne, Evansville, and statewide coverage.

Emergency AC Motor Repair – 24/7 Availability

We understand the urgency of an equipment breakdown. That’s why we offer emergency AC motor repair services 24 hours a day, 7 days a week. We respond quickly, perform precision repairs, and get your equipment back online fast.

Typical 3-Phase Motor Repair Process

-

Data Motor nameplate data is recorded.

-

Inspection A visual inspection of any damage to the motor.

We check for

- Damaged Leads/Terminals

- Worn output shaft/keyways

- Cracks in end bells or covers

- Cracks in motor base

-

Job Ticket We complete to full write up off all motor data.

Including

- All winding tests (Resistance, Meg Ω, Continuity)

- All bearing sizes

- All seal sizes

- Brake torque tests (Record Torque, winding resistance)

- Feedback Tests (Tachometer/Encoder)

-

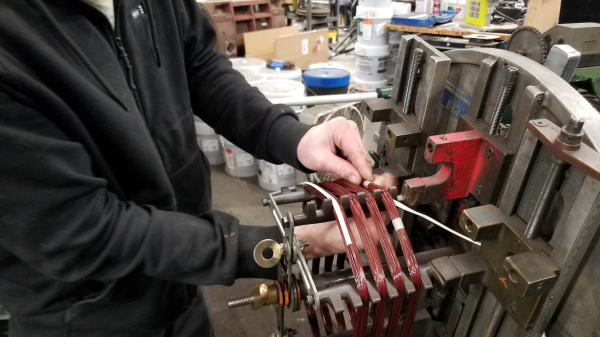

Motor Disassembly

- Bearing and seal sizes are recorded

- Bearing fits are measured on shaft and End bell

- Brake torque is measured as well as resistance and Meg Ω

- More winding tests are performed (Surge and HiPOT tests)

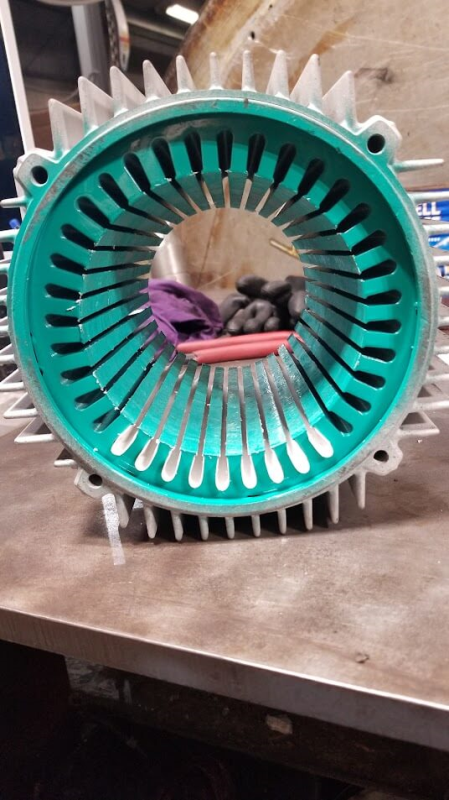

- Stator is then washed and baked in oven (or burned out if required)

- Core test is performed on the stator housing

- Magnets are inspected for cracks

-

Assembly

- New bearings are installed

- New seals are installed

- If required, new windings are impregnated

- Brakes are rebuilt or replaced depending on manufacturer design.

-

Rotor Balancing and Testing

- Rotor is run through a full vibration diagnostic

-

Run Testing

- Every Motor is Run for a minimum of 1 hour using one of our drives.

- We use Siemens S110, S120, IndraDrive, AB Kinetix 300, Yaskawa 7, and AMC drives

-

Service Report

- A Final 3-page Service Report is filled out

- A photo of nameplate and motor is attached

- A motor tag is installed on motor with QR code linking Service Report and Job Histories

- If requested, a YouTube link is attached to the service report of motor

Each job includes a detailed service report outlining the work completed to support long-term planning and reduce the risk of unexpected failures. Our industrial repair capabilities include in-house motor lifting and handling, part fabrication and advanced testing.

Contact A&C Electric to repair your AC 3-phase motor in Michigan, Indiana or Ohio.

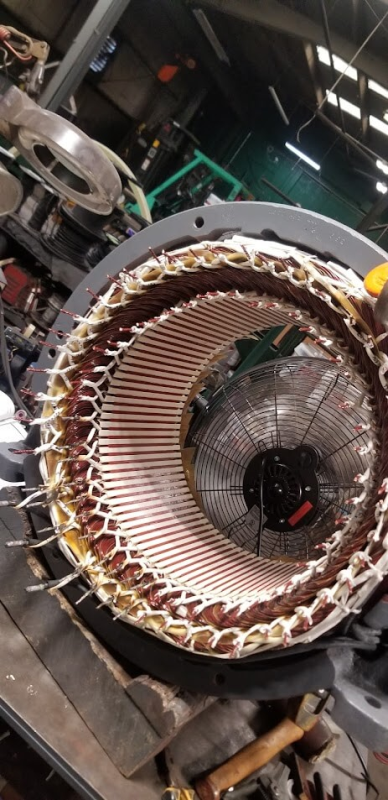

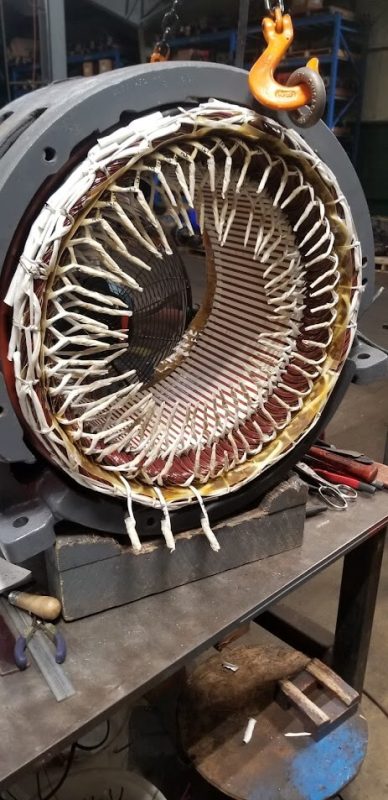

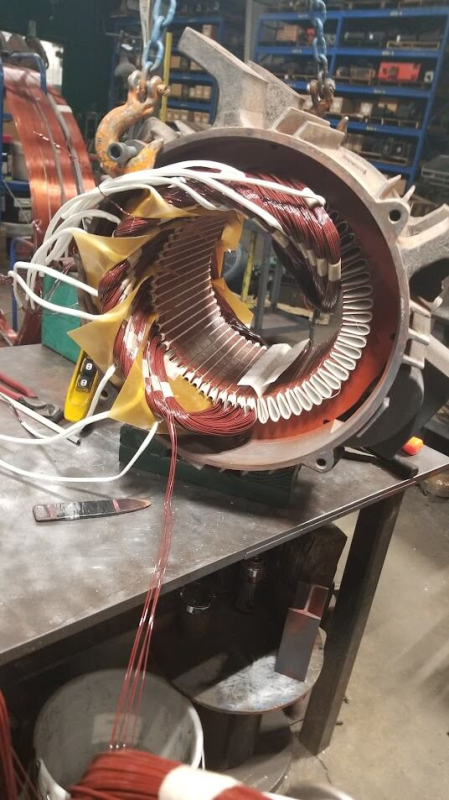

AC 3-Phase Motor Repair in Action

Manufacturers We Service

We repair A.C. 3 phase motors from leading manufacturers across a wide range of applications: